Factory Profiling is the key for SIDF employees to identify digital / traditional factories

Digital Factory:

Digital Factory is a production facility in which people, machines, raw materials and products constantly share information in all stages of the production process. Enabled by Smart Sensors, Smart Products , Smart Operations, Cloud Storage and Big Data Analytics, it combines data and intelligence and integrate them with IT and operational systems.

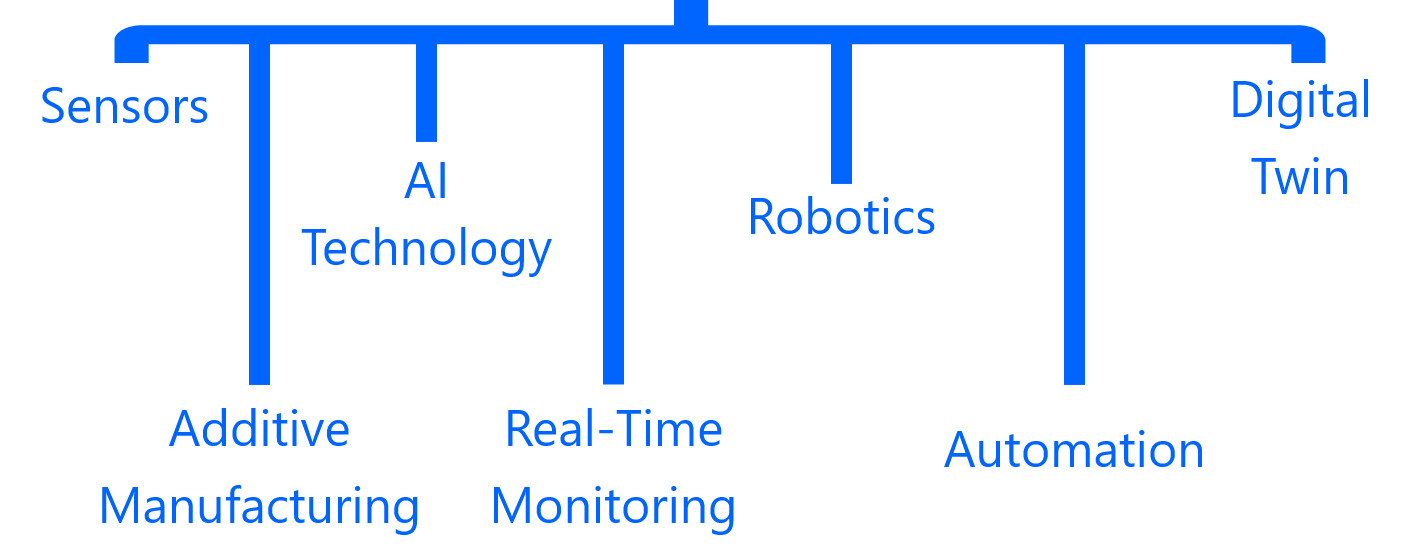

Digital Products:

Digital Products range from Augmented Reality (AR), Artificial Intelligence (AI), Robots and Cobots, Digital Twins, Additive Manufacturing (AM), Sensors, Automation and more, without these products, there will be no digital factory.

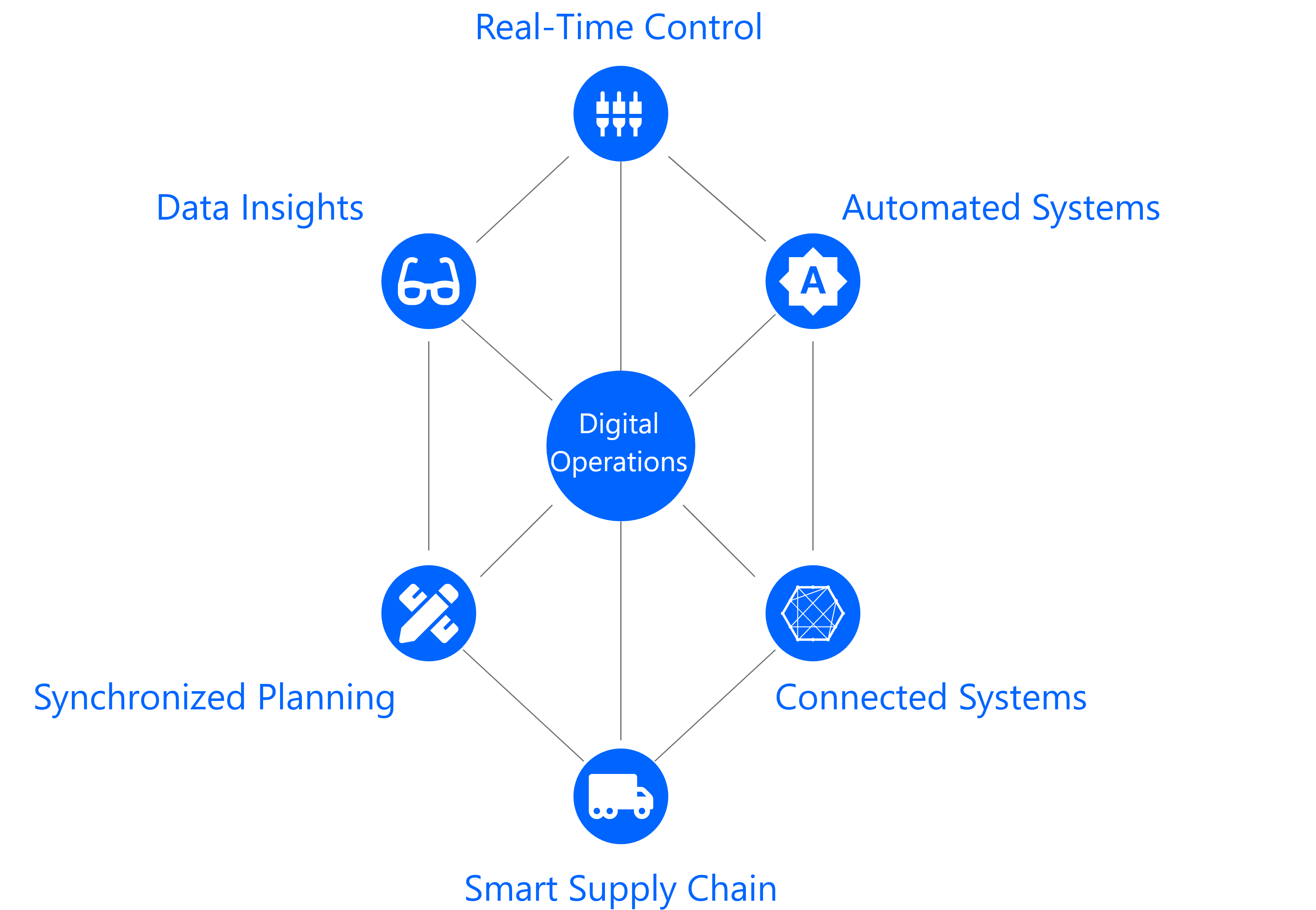

Digital Operations:

Digital Operations combines real-time and continuous data analytics, customer experience and operational execution. Digital Operations Automate and intelligently detect operational errors or opportunities. It delivers real-time measurement and visibility of all aspects of a service or process.

Digital Insights:

Digital Insights are crucial to leverage predictive analytics that are integrated into day-to-day operations to drive decision-making.

Digital Factory Recognition:

Be Able to recognize any digital factory by observing this model which provides key characteristics for any digital factory that implements industry 4.0 solutions.

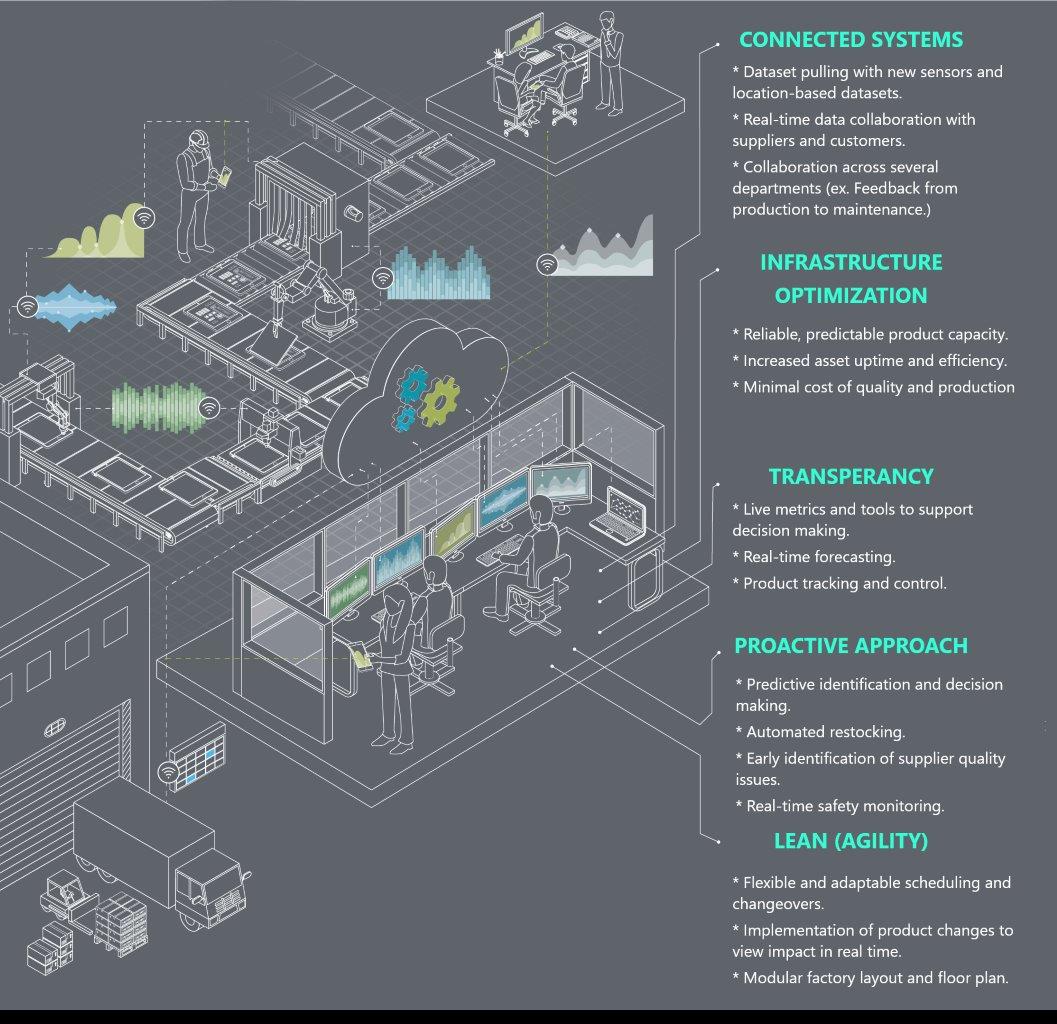

Perhaps the most important

component of the digital factory, it's Connected Ecosysystem,

is

also

one of its most improtant

sources of digitization. Digital factories require the underlying processes and materials to be connected to

generate the

data necessary to make real-time decisions. assets are fitted with smart sensors so

systems can continuously pull data sets from both new and traditional sources, ensuring data are constantly

updated and reflect current conditions. Integration of data from operations and business systems, enables a

holistic view of upstream and downstream supply chain processes, driving

greater overall network efficiency.

An Optimized digital factory allows operations to be

executed

with minimal manual intervention and

high

reliability. The automated workflows, synchronization of assets, improved tracking and scheduling, and

optimized

energy consumption inherent in the digital factory can increase yield, uptime, and quality, as well as

reduce

costs and waste.

In the digital factory, the data captured are Transparent,

Real-time

data visualizations can transform data

captured from processes and fielded or still-in-production products and convert them into actionable

insights,

either for humans or autonomous decision making. A transparent network can enable greater visibility across

the

facility and ensure that the organization can make more accurate decisions by providing tools such as

role-based

views, real-time alerts and notifications, and real-time tracking and monitoring.

In a Proactive Approach, employees and systems can anticipate

and

act before issues or challenges arise, rather

than simply reacting to them after they occur. This feature can include identifying anomalies, restocking

and

replenishing inventory, identifying and predictively addressing quality issues,9 and monitoring safety and

maintenance concerns. The ability of the digital factory to predict future outcomes based on historical and

real-time data can improve uptime, yield, and quality, and prevent safety issues. Within the digital

factory,

manufacturers can enact processes such as the digital twin, enabling them to digitize an operation and move

beyond automation and integration into predictive capabilities.10

Agility allows the digital factory to adapt to schedule

and product changes with minimal intervention.

Advanced digital factories can also self-configure the equipment and material flows depending on the product

being

built and schedule changes, and then see the impact of those changes in real time. Additionally, agility can

increase factory uptime and yield by minimizing changeovers due to scheduling or product changes and enable

flexible scheduling.

These components allow SIDF Officer to identify and profile digital factories, increasing their visibility

across their assets and systems, and allow them to

navigate some of the challenges faced by more traditional factory structures, ultimately leading to improve

their

productivity.

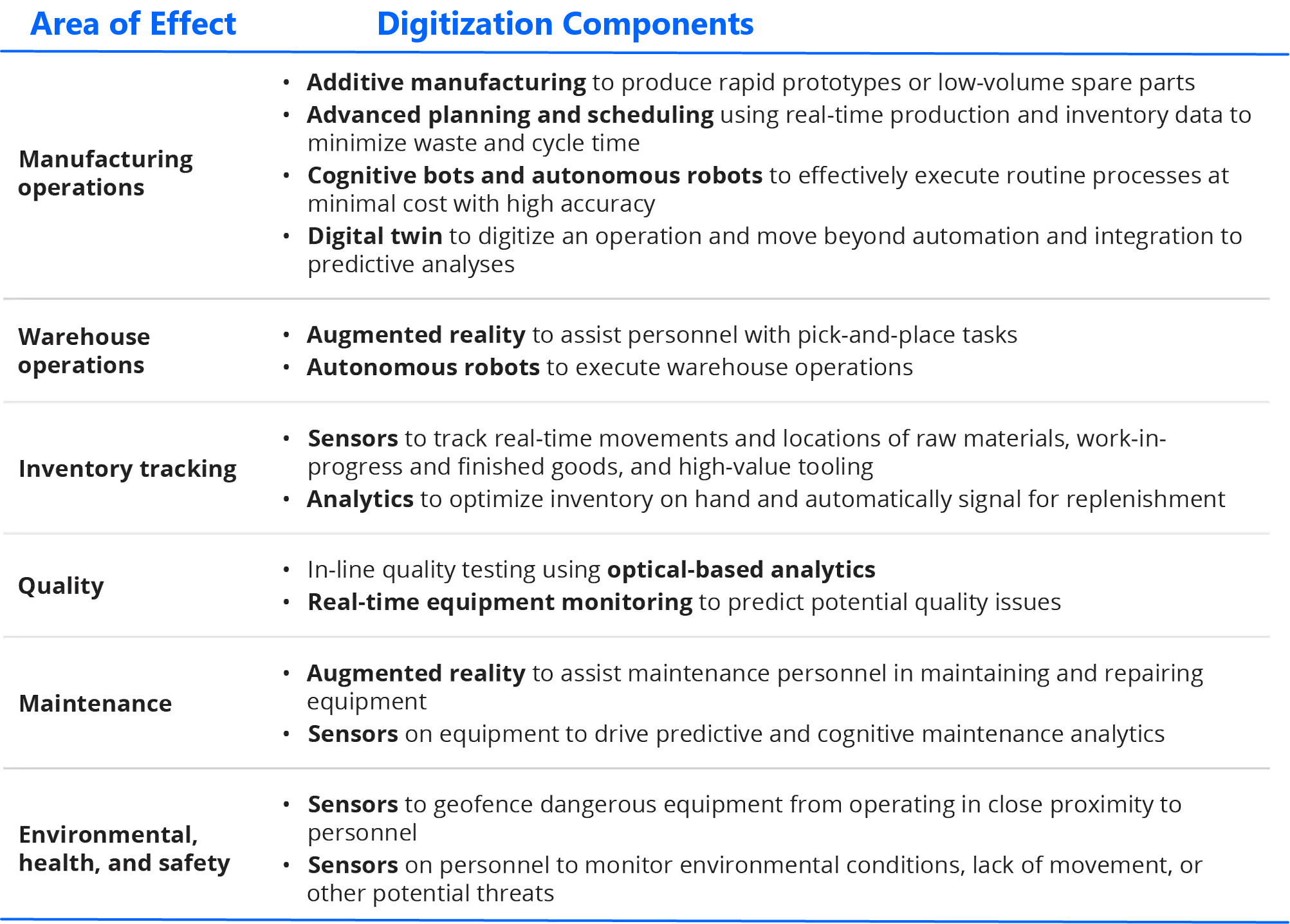

Example of a Digital Factory:

Smart Industrial Readiness Index

(Best way to architect your industry 4.0 transition process)

SIRI Model:

SIRI is divided by

three

sections. At the top are the building blocks of any industrial

organization:

Process

Technology

Organization

following 8

sub sections

of focuses. These focuses has 16 dimensions of assessment, which represent the

key

components that any organization must consider before the digital transformation occurs.

For each of the 16 dimensions, SIDF designator provides an assessment matrix which companies can use to evaluate their current processes, systems, and structures. The assessment matrix also doubles as a step-by-step improvement guide.